Dynamic total temperature sensors or FRETT probes (Fast Response Total Temperature) can measure total temperatures within a periodic flow at very fast rates and with high spatial resolutions. These probes are developed for the operation within turbo machinery, e.g. for dynamic measurements of the change in total temperature within blade channels of gas turbines.

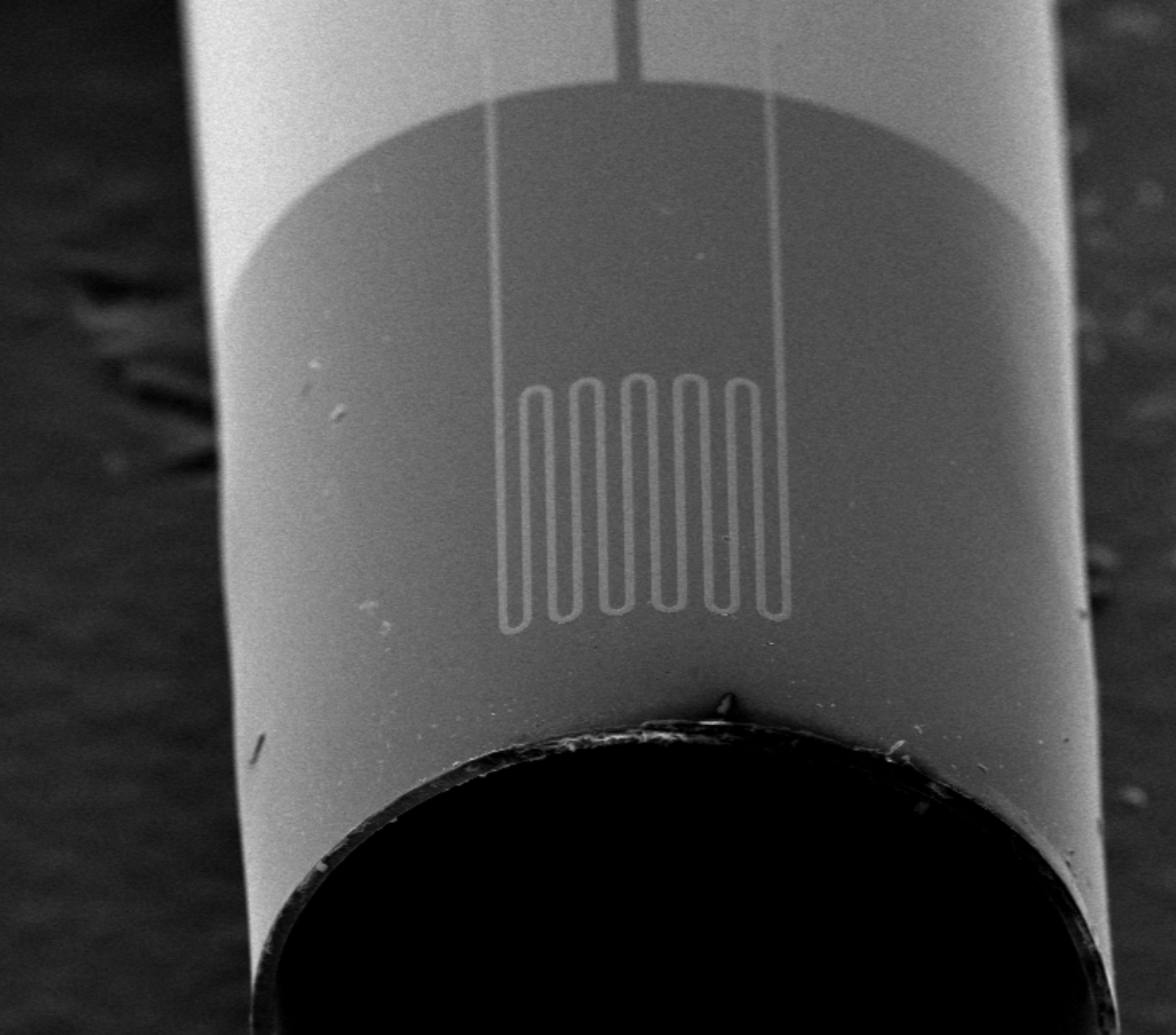

The FRETT probe is a micro platinum resistance sensor. It is distinguished from typically used platinum resistance sensors (e.g. Pt100) through an extremely small sensing surface with a resistance range between 550 and 2800 ohm allowing an acquisition rate larger than 50 kHz at a resolution if 1 K/µs.

The temperature dependent resistance is supplied with constant reference currents via a DC source. In case of a change in temperature the voltage leads to the respective resistance change in the sensor element. Using a revolution controlled trigger signal voltage measurements are executed with a fixed sensor position inside the turbine blade channel at periodic flow conditions (same rotor speed).

The platinum meander of the FRETT probe can be delivered in various designs. These designs differ in terms of width and distance of the conductive paths. In this way several different resistances can be realized. The total size of the sensor element remains extensively constant with an area of 0.14 up to 0.15 mm2.

FRETT-Probe Patents:

WO 2010/142307 A1

US 2012/114011 A1

Functions

- Dynamic total temperature measurement

- Determination of complete temperature distributions

- High spatial resolution (0.14 mm2)

- High temporal resolution (≥ 50 kHz)

- High temperature resolution (1 K/µs)

- Four-terminal sensing